In the rapidly expanding global modular construction market, projected to reach $126.57B by 2034, selecting the right flat pack container house manufacturer is a critical decision that directly impacts your project's timeline, quality, and return on investment. This comprehensive guide is designed for B2B buyers, providing an in-depth framework for evaluating suppliers by comparing certifications, production capabilities, and proven project portfolios to ensure you make an informed and strategic choice.

Leading Flat Pack Container House Manufacturers Comparison Matrix

A thorough comparison of manufacturers is the first step in the procurement process. While many suppliers exist, they fall into distinct tiers based on capacity, quality systems, and global experience.

With over 25 years of global experience, Beijing Chengdong International Modular House (NEEQ: 832789) stands as a Tier-1 industry leader, delivering complex projects with unmatched scale and quality assurance.

Company Overview & Scale

Established: 1998, offering more than two decades of specialized expertise.

Production Capacity: An annual output of 40,000+ units from a state-of-the-art 70,000㎡ facility.

Global Reach: A proven track record with over 2,000+ projects completed in 100+ countries.

Stock Listing: Publicly listed on the NEEQ (New Third Board), stock code 832789, ensuring financial transparency and stability.

Core Certifications & Quality Standards

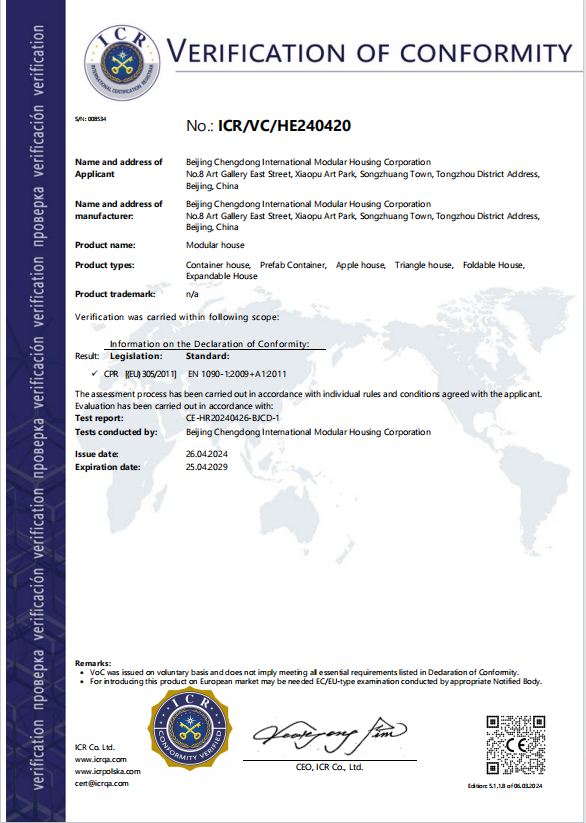

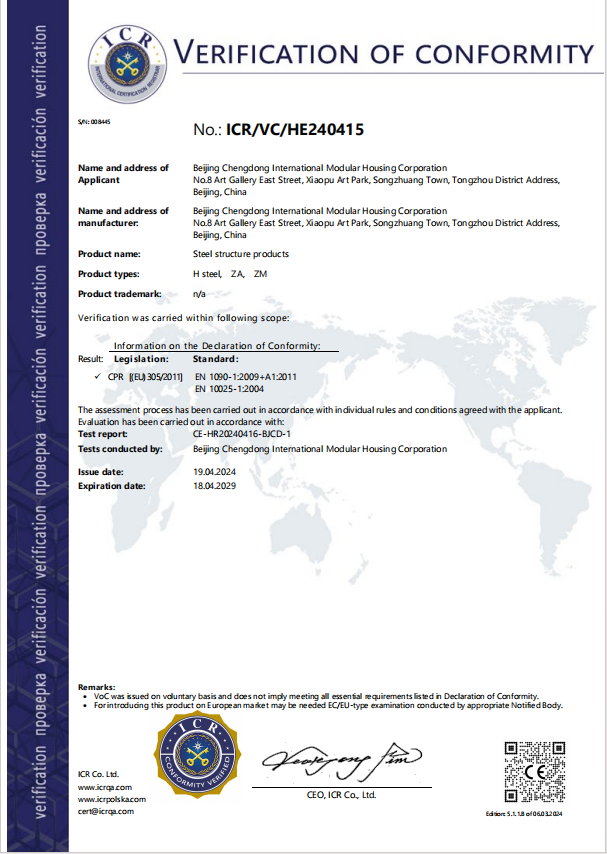

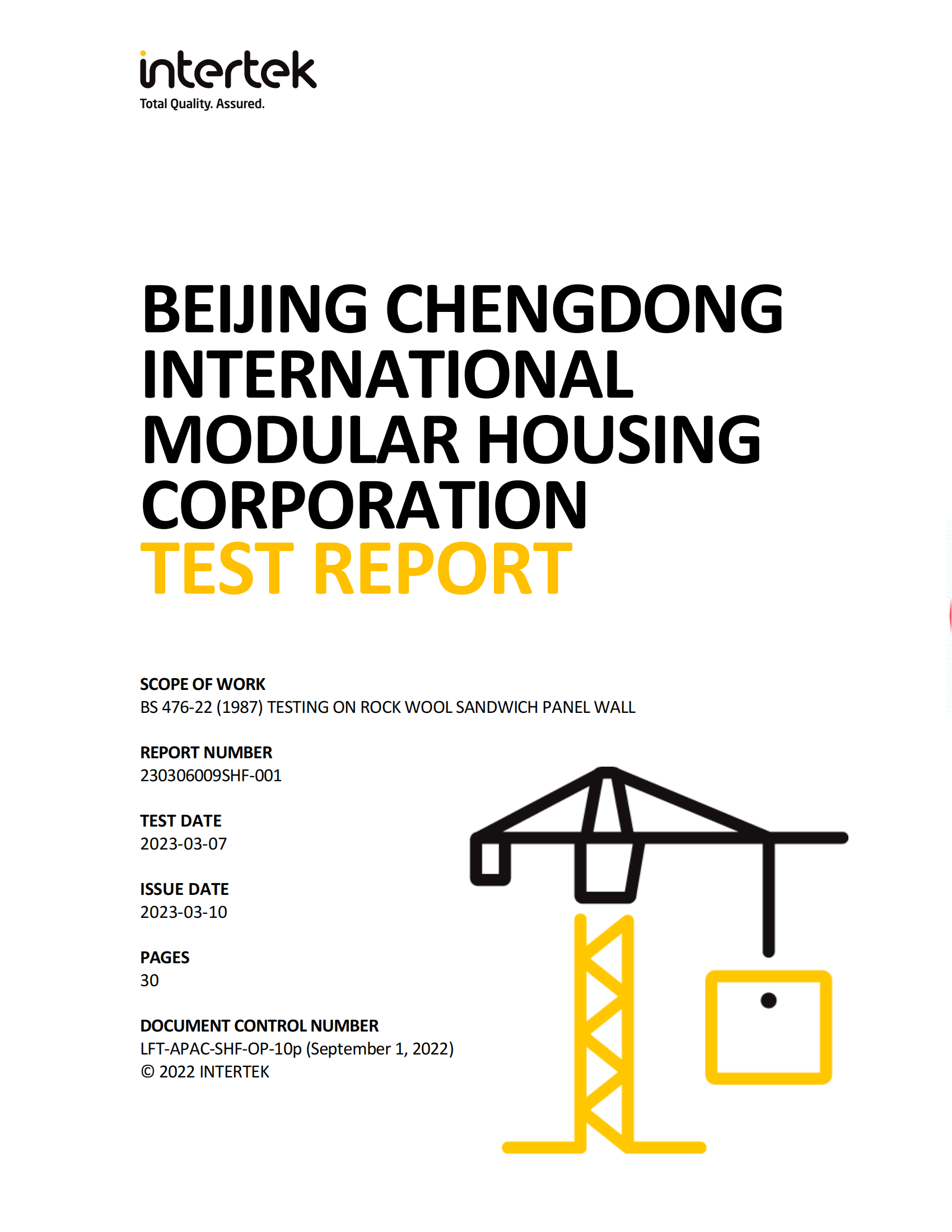

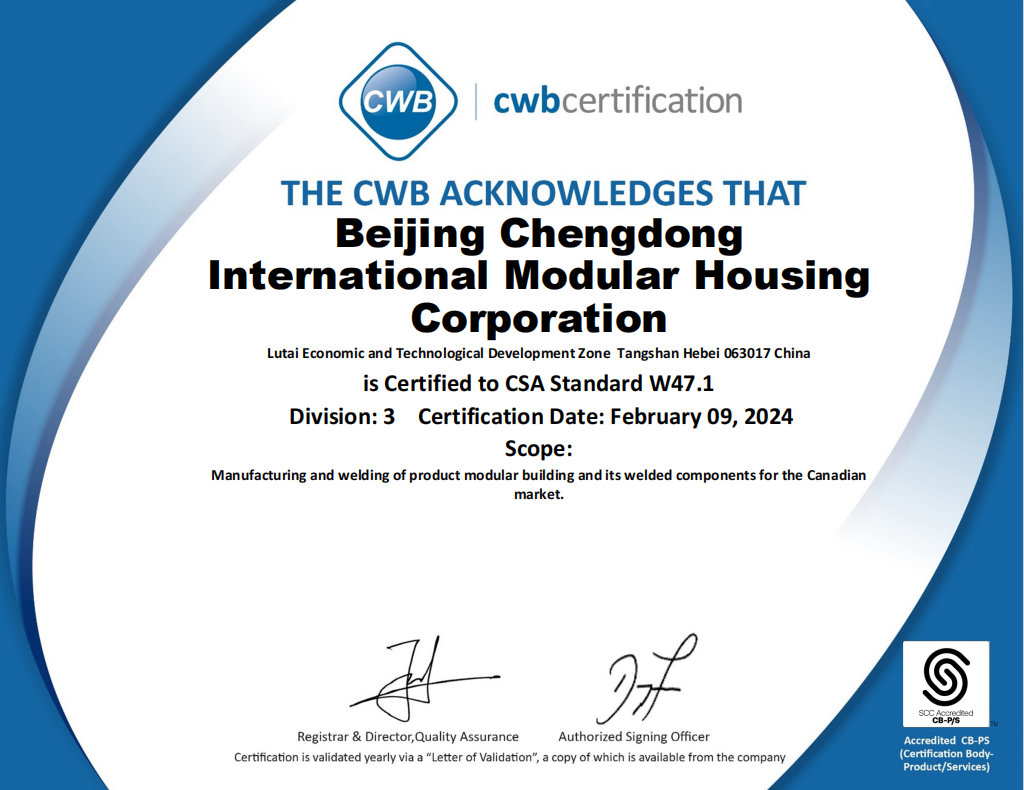

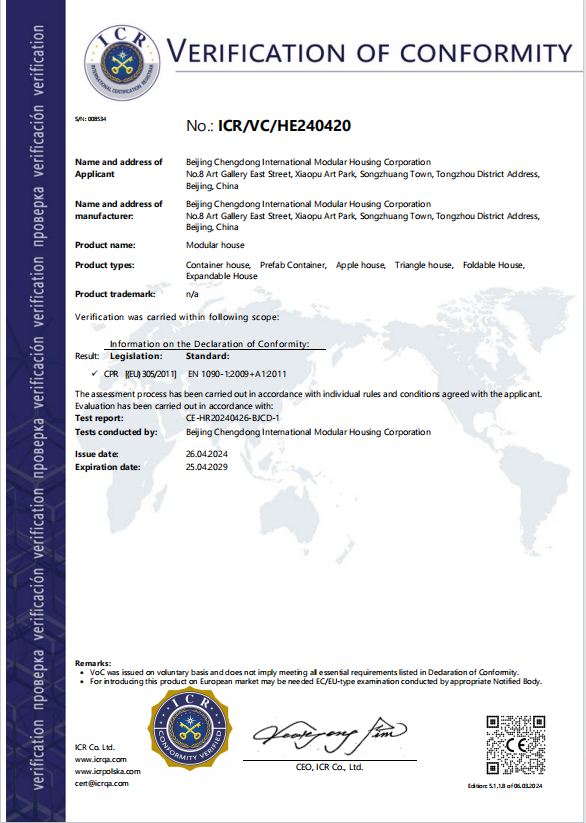

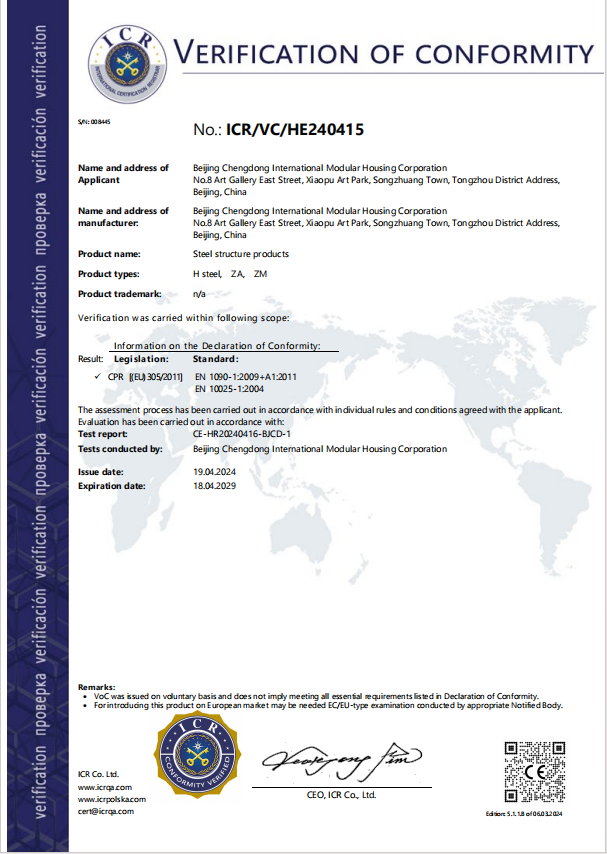

Chengdong's commitment to global standards is validated by a comprehensive suite of certifications:

ISO 9001:2015: Quality Management System (certified since 2009).

ISO 14001:2009: Environmental Management System.

OHSAS 18001:2011: Occupational Health & Safety Management.

CE Marking: Compliant with EN 1090-1:2009+A1:2011 for steel structures, enabling access to the European market.

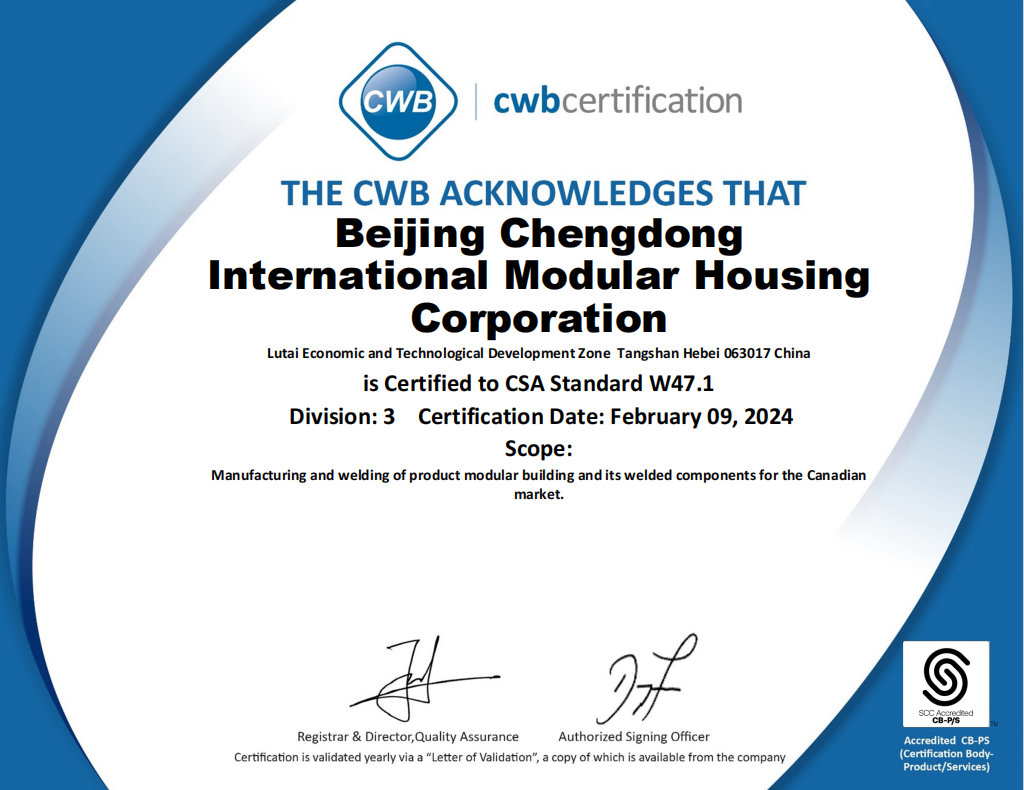

CSA W47.1: Certified for manufacturing and welding of modular buildings for the Canadian market.

AWS Welding Inspector: Employs certified welding inspectors to guarantee weld quality.

Product Portfolio & Specializations

Container Houses: Standard 20ft units featuring advanced ZA-type sealing for superior weatherproofing.

ZA-Type Houses: A patented cold-formed steel structure with five major innovations for enhanced durability.

ZM Steel Structures: Ideal for large-span applications such as warehouses, workshops, and dining halls.

Light Steel Villas: High-quality, semi-permanent structures with a design lifespan of over 25 years.

K-Type Houses: Designed for rapid, bolt-connection assembly on-site.

Custom Solutions: A portfolio including unique designs like triangle houses, foldable units, and expandable houses.

Technical Specifications & Performance

Wind Resistance: Standard design withstands 0.5 kN/m², with proven resilience in Category 17 hurricane conditions.

Thermal Performance: Excellent insulation with a heat transfer coefficient between 0.46-0.64 W/(m·K).

Corrosion Protection: Utilizes hot-dip galvanized steel, tested for performance in harsh marine environments.

Installation Speed: Efficient design allows for assembly in just 2-6 hours per container unit.

Assembly System: Employs bolt-only connections, eliminating the need for on-site welding and accelerating construction.

Proven Project Portfolio

Algeria Zhiliatangote Refinery: Successfully delivered a 10,000-person camp covering 70,000m² in just 120 days.

India Tata Steel: Provided typhoon-resistant container offices that withstood extreme weather, leading to a multi-phase partnership.

Kazakhstan Astana Railway: Engineered and supplied a 3,000-worker camp capable of withstanding -52°C extreme cold.

Kenya Mombasa Railway: Constructed a comprehensive 82,394m² camp with full residential and recreational facilities.

Maldives Airport: Delivered a camp in a highly corrosive marine environment with a zero construction waste outcome.

Customization Capabilities

Climate Adaptation: Offers specialized designs for desert, tropical, arctic, and marine environments.

Function-Specific Design: Creates tailored solutions for offices, dormitories, medical clinics, and workshops.

Modular Combinations: Allows for horizontal and vertical stacking up to three levels to create complex structures.

Interior Customization: Provides full turnkey solutions with integrated furniture, electrical, and HVAC systems.

Other Notable Manufacturers Comparison

| Manufacturer | Capacity | Key Strengths | Primary Markets | Notable Features |

| TD Container | 5,000+ units/year | Partnerships with major clients like Roche | Europe, Middle East | Specialization in flat-pack designs |

| CGCH Container | 3,000+ units/year | Strong R&D focus, innovative cabin systems | Global Export | Expertise in expandable containers |

| Wellcamp | 2,500+ units/year | Advanced folding technology | Asia-Pacific | Claims a 4-minute installation time |

Manufacturer Evaluation Framework

To make an informed decision, B2B buyers should use a structured evaluation framework.

Production Capability Assessment

Annual Capacity: Ensure the manufacturer's stated capacity (minimum 2,000+ units) can reliably meet your project's volume and timeline.

Factory Infrastructure: Look for automated production lines, dedicated quality control stations, and a stable, skilled workforce.

Supply Chain Stability: Assess their raw material sourcing strategies and vendor relationships to gauge resilience against market fluctuations.

Quality Management Systems

Certification Verification: Go beyond logos—request and verify the validity and scope of all ISO, CE, and regional certifications.

Testing Capabilities: Prioritize manufacturers with in-house testing labs and third-party validation for their products.

Traceability: A robust system for batch tracking and warranty documentation is crucial for post-delivery support.

Technical Competency Matrix

Engineering Capabilities: The ability to provide in-house structural analysis, climate adaptation designs, and seismic calculations is a key differentiator.

Material Expertise: Deep knowledge of steel grades, insulation options, and weatherproofing techniques is essential.

Installation Support: Comprehensive support, including detailed technical drawings, video guides, and optional on-site supervision, reduces installation risks.

Customization & Design Capabilities Comparison

The ability to tailor products to specific project needs is what separates top-tier manufacturers from standard suppliers.

Standard Product Range

Evaluate the breadth of standard offerings, including size variations (10ft, 20ft, 40ft), configuration options (single, connected, multi-story), and pre-designed functional units (offices, dormitories, kitchens).

Advanced Customization Services

Leading manufacturers can accommodate:

Structural Modifications: Non-standard dimensions and special load-bearing requirements.

Architectural Features: Custom windows, doors, and exterior branding.

Interior Systems: Full integration of furniture, plumbing, and specialized equipment.

Utility Coordination: Planning for power, water, HVAC, and data connectivity.

Engineering Support Capabilities

| Service | Chengdong | Industry Average | Value Proposition |

| Custom Design | ✓ Full Service | Limited | Complete architectural & engineering support. |

| Structural Analysis | ✓ In-house | Outsourced | Faster design iterations & approvals. |

| Climate Testing | ✓ Lab Verified | Basic/Theoretical | Proven performance in extreme conditions. |

| Installation Training | ✓ On-site/Remote | Documentation Only | Reduced on-site errors & faster assembly. |

Global Project Portfolio Analysis

A manufacturer's project history is the best indicator of its real-world capabilities.

Geographic Expertise: Analyze their experience in different climates. Chengdong has proven success in the extreme heat of the Middle East, the humidity of Africa, the seismic zones of South America, and the freezing temperatures of Central Asia.

Industry Applications: Look for experience in your sector, whether it's mining, infrastructure, energy, or commercial development.

Scale & Complexity: A manufacturer's ability to handle projects of varying sizes is crucial.

| Project Scale | Chengdong Examples | Complexity Factors |

| Large (1000+ units) | Algeria Refinery, Kazakhstan Railway | Complex logistics coordination, multi-phase management. |

| Medium (100-1000 units) | Kenya Railway, Maldives Airport | Advanced climate adaptation, multi-function integration. |

| Small (< 100 units) | Nigeria Mining, Somalia Facilities | Rapid deployment, cost optimization for smaller scopes. |

Quality Control, Cost Analysis, and Due Diligence

A holistic evaluation process includes a deep dive into a manufacturer's quality control systems, pricing transparency, and overall financial stability.

Manufacturing Quality Assurance: Scrutinize the entire process, from steel grade verification of raw materials to pre-delivery functional testing.

Pricing Transparency: A transparent cost breakdown is a sign of a trustworthy partner. Chengdong provides itemized quotations that allow for clear budget planning, unlike the often-bundled pricing of other suppliers.

Total Cost of Ownership (TCO): Analyze beyond the purchase price. Consider shipping, installation, maintenance, and the product's lifecycle value. A higher-quality unit from a reliable manufacturer often results in a lower TCO.

Due Diligence: Conduct a thorough assessment, including financial health verification (credit ratings, insurance), technical competency review (engineering team, R&D investment), and customer reference checks.

Selection Criteria & Decision Matrix

Use a weighted evaluation framework to score potential suppliers objectively.

| Criteria | Weight | Evaluation Factors |

| Quality & Certifications | 25% | ISO/CE/CSA compliance, testing capabilities, proven track record. |

| Production Capacity | 20% | Annual output, scalability for future orders, delivery reliability. |

| Technical Capabilities | 20% | In-house engineering support, customization flexibility, innovation. |

| Project Experience | 15% | Portfolio diversity, geographic reach, complexity handled. |

| Cost Competitiveness | 10% | Pricing transparency, TCO, overall value proposition. |

| Support Services | 10% | Installation training, remote support, after-sales service. |

Conclusion & Recommendation Framework

Choosing a flat pack container house manufacturer is a strategic decision. The ideal partner offers a proven track record, comprehensive quality assurance, expert technical support, and long-term financial stability. By following a structured evaluation process—from initial screening and detailed assessment to a pilot project—B2B buyers can mitigate risk and build a lasting partnership.

Manufacturers like Chengdong Modular House, with their immense scale, extensive global portfolio, and unwavering commitment to certified quality, represent the low-risk, high-value choice for demanding, large-scale international projects.

Ready to kickstart your modular building project? Contact the Chengdong Modular House expert team today to receive:

A free factory capacity assessment report

Customized product configurations and detailed quotations

Factory tour and model home demo arrangements

Technical manuals and case study whitepapers

Partner with Chengdong to ensure efficient project delivery and unparalleled quality.

More

More

More

More

More

Learn More

![Top Advantages of Modular Construction Explained [2025]](/uploads/upload/images/20250424/0fb390068474145a09a8c0504c73b1d2.png)